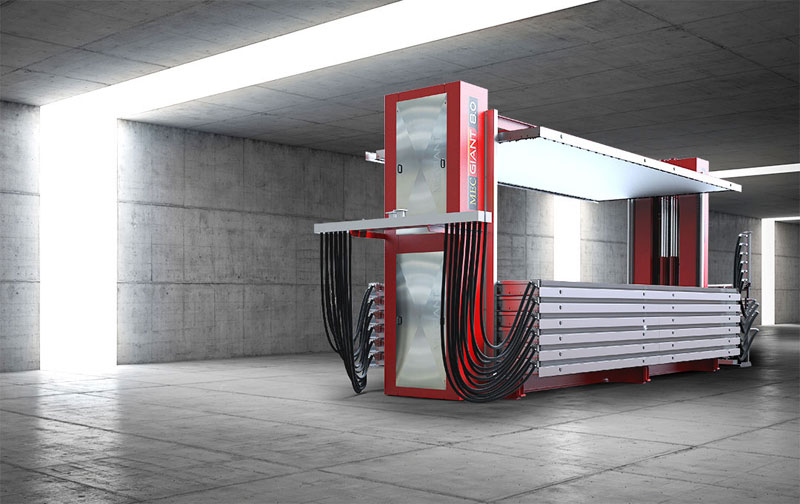

We present our workhorse: the vacuum MecGiant 8.0 mt.

The evolution of the classical systems of vacuum drying, made with craftsmanship, materials and components of highest quality, using the tables of 8.0 mt, which allow to increase production at reduced costs.

Why would a customer buy the MecGiant 8.0 mt. compared to a 7.0 m. that is the standard of the specific of the last 25 years?

1°) so that with our dryer and it increases and improves the production in the same time

2°) as it decreases management costs and power consumption.

The evolution MecGiant is, in fact, to propose plans of large dimensions: 8.0 mt, but also 8.6 and 9.0 mt. maintaining the exceptional characteristics of rigidity, flexibility and harmony of movement and, at the same time, increasing production and reducing consumption.

Let’s take the example of buffalo hides. Passing by a surface of 7.0 to 8.0 mt, for a 6-layer vacuum dryer, the production increases by 33%.

This means 6 extra hides for each working cycle and, assuming a 16-hour day of work of the machine, at the end of the day we will have 576 extra skin dry. That, in a year, making a total of 140.000 skins in more.

Skin smooth and natural, that once dry, are already cool to the touch and very soft, due to the significant decrease of the drying temperature (-20%), the system MecGiant allows you to get.

The important technological innovations made by Mec Man, in fact, reduce the electrical power consumption of the 5% and heat by up to 40%.

To read the interview click here